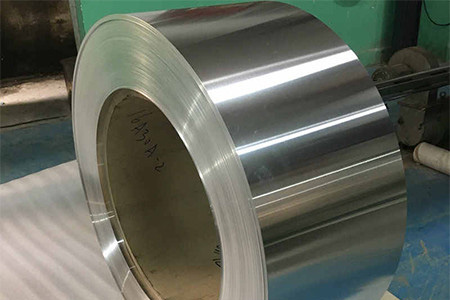

How to distinguish the quality of stainless steel pipes

Material of stainless steel pipes is the basic of stainless steel pipes quality. The corrode resistance of 316 stainless steel pipes is higher than 304 stainless steel pipes. So, how do we distinguish the material of stainless steel pipes?